Roll Forming is a fast and effective profile

production method designed to manufacture

large quantities of profiles (Mass Production).

The profiles can be in any shape

with punching during the process.

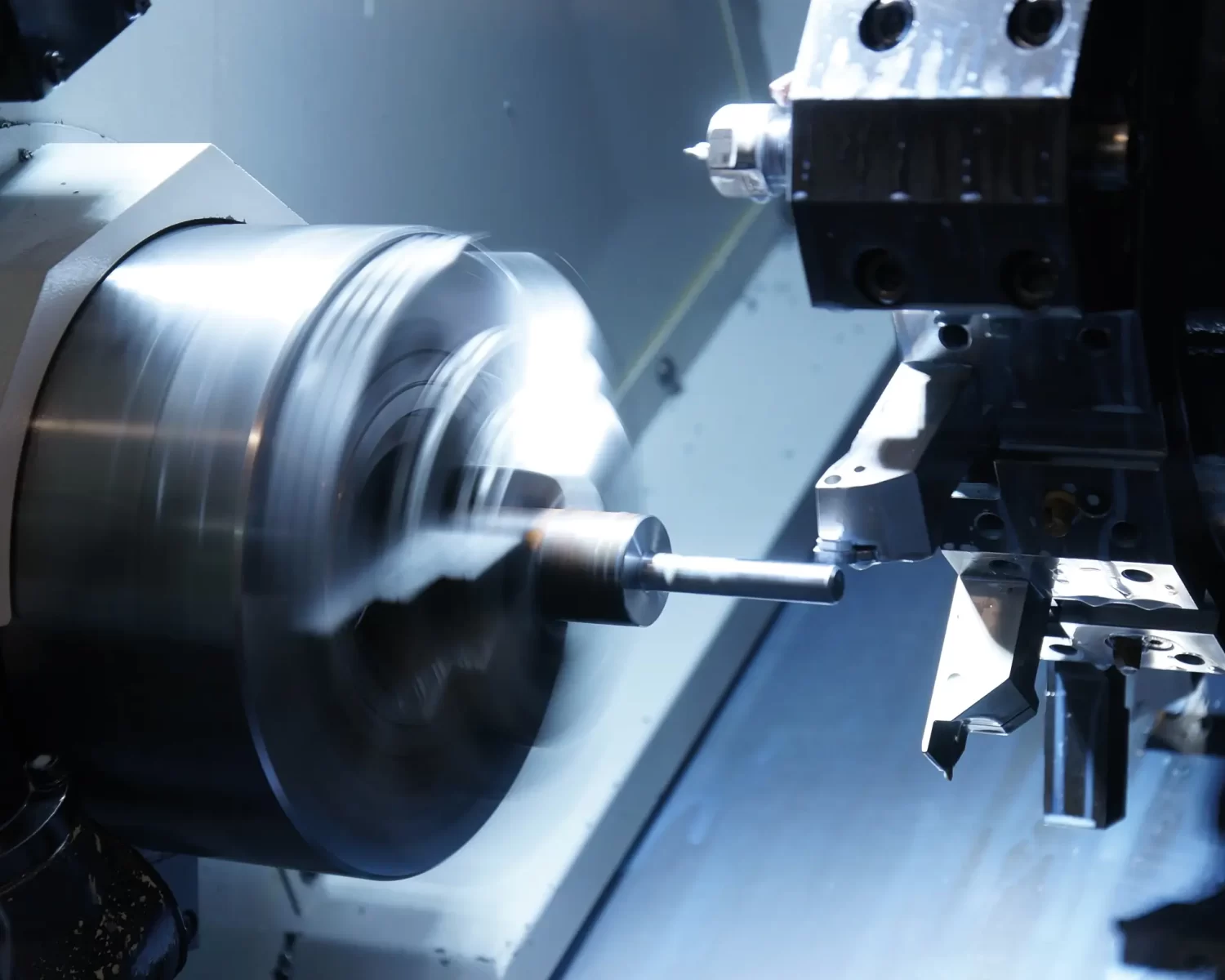

The process begins by building and adapting the machine to the type of rolls by making unique rolls that form the shape of the profile.

In the process, a flat sheet of galvanized metal and aluminum is inserted and goes through the set of rolls while punching until the final result is achieved – a profile. The profiles can also be painted as needed.

Incomac Blocker has 13 efficient machines which produce millions of meters of profiles annually. Its primary customers are global companies in the DIY industry, such as Keter Plastic, Stanley, Palram Applications, and more.

Incomac Blocker’s Roll Forming Department is top of its feild with more than 35 years of experience.